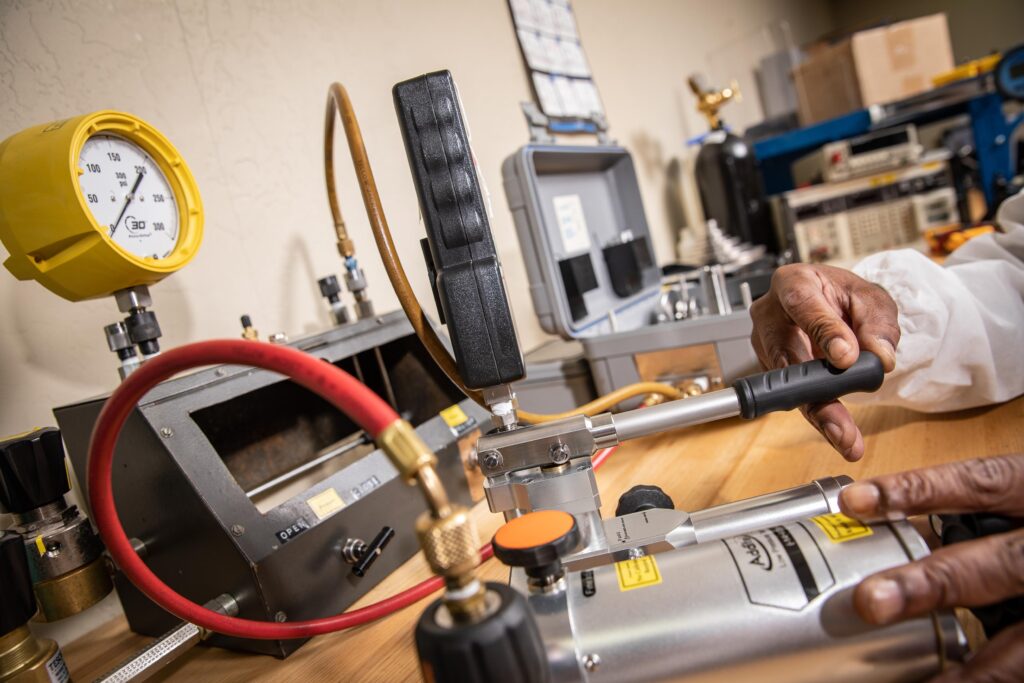

In the world of metrology, precision is paramount. The integrity of measurements and the safety of operations often hinge on the accurate performance of critical instruments like oxygen pressure gauges. These devices, which measure the pressure of oxygen in various industrial and medical settings, must be meticulously maintained and cleaned to ensure their accuracy and reliability. Contaminants can not only skew readings but also pose serious safety hazards.

The Importance of Clean Oxygen Pressure Gauges

Oxygen pressure gauges play a crucial role in healthcare, aerospace, and manufacturing. Contaminants such as oil, grease, and other residues can significantly impair the function of these gauges. Even minute particles can affect the sensitivity and accuracy of the measurements, leading to potentially dangerous situations.

Proper cleaning of oxygen pressure gauges is not just about maintaining accuracy; it’s also about preventing hazardous reactions. Oxygen is a highly reactive gas, and when it comes into contact with certain contaminants, it can cause fires or explosions. Ensuring that gauges are free from any trace of contaminants is essential for the safety of both personnel and equipment.

Introducing the King Nutronics 3646

To address the critical need for meticulous cleaning of oxygen pressure gauges, we have invested in the King Nutronics 3646. This state-of-the-art cleaning system is specifically designed to ensure that gauges are free of any contaminants. The King Nutronics 3646 combines advanced technology with rigorous cleaning processes to deliver unparalleled results.

This unit uses a combination of ultrasonic cleaning and advanced filtration systems to remove all traces of contaminants from the gauges. The ultrasonic cleaning process involves submerging the gauges in a cleaning solution and using high-frequency sound waves to create microscopic bubbles. These bubbles implode on the surface of the gauges, effectively dislodging and removing contaminants. The advanced filtration system ensures that any particles or residues are completely removed from the cleaning solution, preventing recontamination.

Benefits of the King Nutronics 3646

The King Nutronics 3646 offers several key benefits that enhance the cleaning process and ensure the highest standards of safety and accuracy:

1. Thorough Cleaning:

The ultrasonic cleaning process reaches all surfaces of the gauges, including hard-to-reach areas, ensuring complete removal of contaminants.

2. Enhanced Safety:

By ensuring that gauges are free of any potentially reactive contaminants, the risk of fire or explosion is significantly reduced.

3. Improved Accuracy:

Clean gauges provide more accurate readings, which is essential for maintaining the integrity of measurements in critical applications.

4. Efficiency:

The King Nutronics 3646 streamlines the cleaning process, reducing the time and effort required to achieve optimal results.

Conclusion

In the field of metrology, the importance of maintaining clean and accurate oxygen pressure gauges cannot be overstated. The King Nutronics 3646 represents a significant advancement in the cleaning and maintenance of these critical instruments. By investing in this state-of-the-art system, we are committed to ensuring the highest standards of safety and accuracy for our clients.

Proper handling and regular cleaning of oxygen pressure gauges enhance their performance and safeguard the well-being of those who rely on their precise measurements. With the King Nutronics 3646, we are well-equipped to meet these stringent requirements, providing our clients with the confidence and reliability they need in their operations.