In the fast-paced world of modern industry, precision and accuracy are paramount. Companies across various sectors rely on intricate machinery and equipment to maintain efficiency and produce high-quality products. This is where calibration services step in, playing a crucial role in ensuring that instruments and devices function at their optimal levels. In this blog post, we’ll delve into why calibration services are essential and explore the profound impact they have on companies that prioritize accuracy and reliability.

Understanding Calibration Services

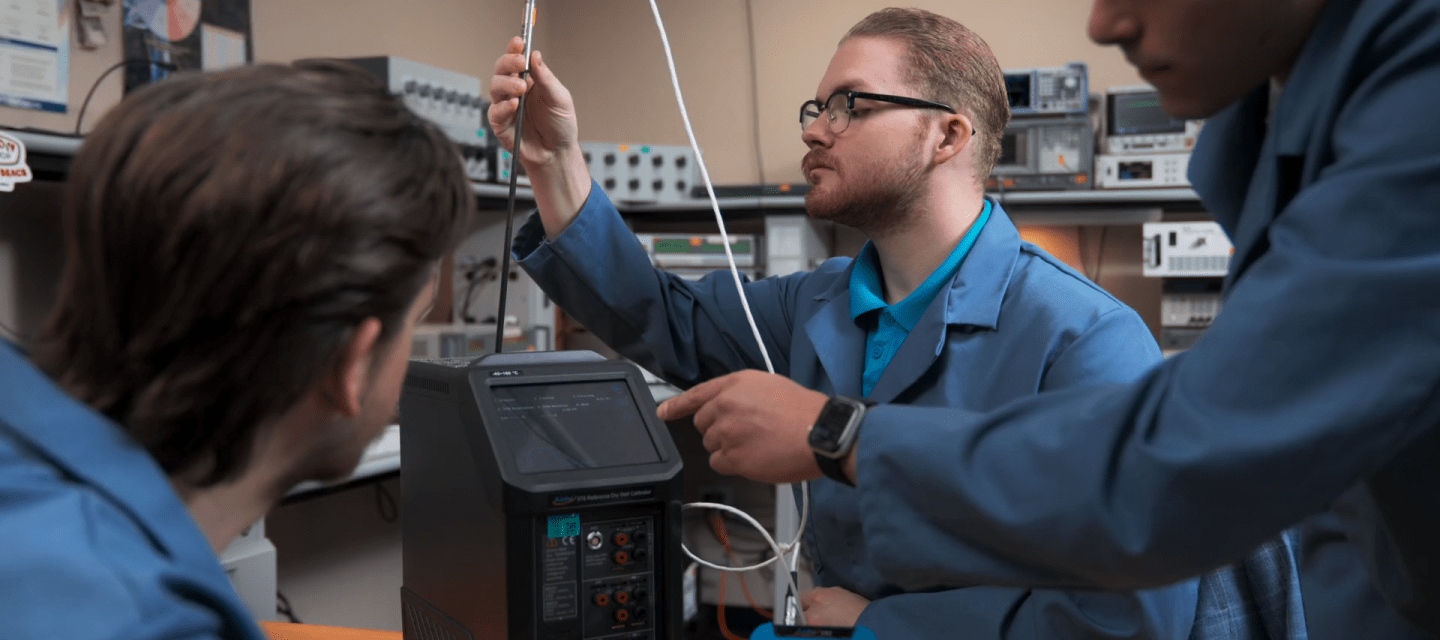

Calibration is a systematic process of adjusting and verifying the accuracy of measurement instruments. This service involves comparing the readings of an instrument to a known reference standard, identifying any discrepancies, and making necessary adjustments to bring the device back to its specified accuracy. Calibration is not only about maintaining accuracy but also about meeting industry standards and regulatory requirements.

Maintaining Compliance and Quality

One of the primary reasons why calibration services are indispensable for companies is compliance. In many industries, there are stringent regulations and standards that dictate the precision of measurements and the accuracy of instruments. Compliance with these standards is not just a legal requirement but also a mark of commitment to quality and reliability.

For instance, in the pharmaceutical and healthcare sectors, calibrated equipment is crucial to ensure accurate dosages and test results. Similarly, manufacturing industries rely on calibrated instruments to maintain consistency in production processes. Non-compliance can lead to faulty products, financial losses, and even legal consequences. Calibration services act as a safeguard against such risks, ensuring that a company’s instruments meet or exceed the necessary standards.

Enhancing Reliability and Efficiency

Precision is a key factor in the reliability and efficiency of any operation. When instruments are accurately calibrated, companies can trust the measurements they provide. This, in turn, leads to more dependable processes, reducing the likelihood of errors and rework. In industries where precision is vital, such as aerospace or automotive manufacturing, the impact of calibrated instruments on efficiency is monumental.

Calibrated equipment also plays a significant role in reducing downtime. Unplanned downtime due to inaccurate measurements or faulty instruments can result in production delays, increased costs, and frustrated customers. Calibration services contribute to preventive maintenance, identifying potential issues before they lead to operational disruptions. This proactive approach enhances overall efficiency and productivity.

Cost Savings Through Calibration

While some companies might view calibration as an additional expense, it is crucial to recognize the long-term cost savings associated with it. Calibrated instruments are less likely to produce defects or errors, reducing the need for rework and minimizing waste. Moreover, accurate measurements contribute to optimal resource utilization, preventing overuse of materials and energy.

In industries where precision is critical, like scientific research or semiconductor manufacturing, the cost of inaccuracies can be astronomical. Calibration services provide the assurance that the measurements obtained are reliable, leading to significant cost savings in the long run.

Conclusion:

In conclusion, calibration services are not just a technical requirement but a strategic investment for companies aiming to excel in their respective industries. The impact of accurate measurements on compliance, reliability, efficiency, and cost savings is undeniable. By prioritizing calibration, companies ensure that their instruments are not just tools but reliable assets contributing to their success. In a world where precision is paramount, calibration services emerge as the unsung heroes, silently but significantly influencing the trajectory of businesses that prioritize accuracy and excellence.