In today’s rapidly evolving world, where technological advancements and innovations occur at an unprecedented pace, the importance of metrology and calibration cannot be overstated. Metrology, the science of measurement, and calibration, the process of ensuring measurement accuracy, play crucial roles in maintaining the integrity, safety, and efficiency of various industries. From aerospace and automotive to healthcare and telecommunications, metrology and calibration form the backbone of modern advancements, ensuring that new technologies function as intended and meet rigorous standards.

The Role of Metrology in a Fast-Paced World

As the world continually pushes the boundaries of what is possible, metrology ensures that these advancements are not only achievable but also reliable and precise. In sectors where precision is paramount, such as manufacturing and pharmaceuticals, accurate measurements are critical. For instance, in the production of microprocessors, even the smallest deviation in measurement can lead to significant failures. Metrology ensures that these measurements are accurate to the nanometer, enabling the production of high-performance and reliable products.

Moreover, in the realm of scientific research, metrology provides the foundation for experimental validation and replication. Precise measurements enable scientists to accurately test hypotheses, leading to groundbreaking discoveries and innovations. Without metrology, the repeatability and reliability of scientific experiments would be compromised, hindering progress and innovation.

Milestones and Advancements in Metrology Over the Last 20 Years

Over the past two decades, the field of metrology has witnessed significant advancements, driven by the need to keep up with technological advancements. One of the most notable milestones is the redefinition of the International System of Units (SI) in 2018. This redefinition, based on fundamental physical constants rather than physical artifacts, marked a significant shift towards more stable and universally accessible standards. For example, the kilogram is now defined by the Planck constant, ensuring greater accuracy and stability in measurements.

Another significant advancement in metrology is the development of quantum metrology. Utilizing principles of quantum mechanics, quantum metrology has pushed the boundaries of measurement precision, enabling unprecedented levels of accuracy. This has profound implications for various industries, including telecommunications, where ultra-precise measurements are crucial for the development of quantum communication systems.

Advancements have revolutionized the way measurements are conducted and analyzed. The integration of digital technologies, such as digital twins and artificial intelligence, has enhanced the accuracy, efficiency, and speed of measurements. These advancements in metrology enable real-time monitoring and analysis, reducing the margin of error and facilitating faster decision-making processes.

Evolving to Keep Up with Modern Advancements

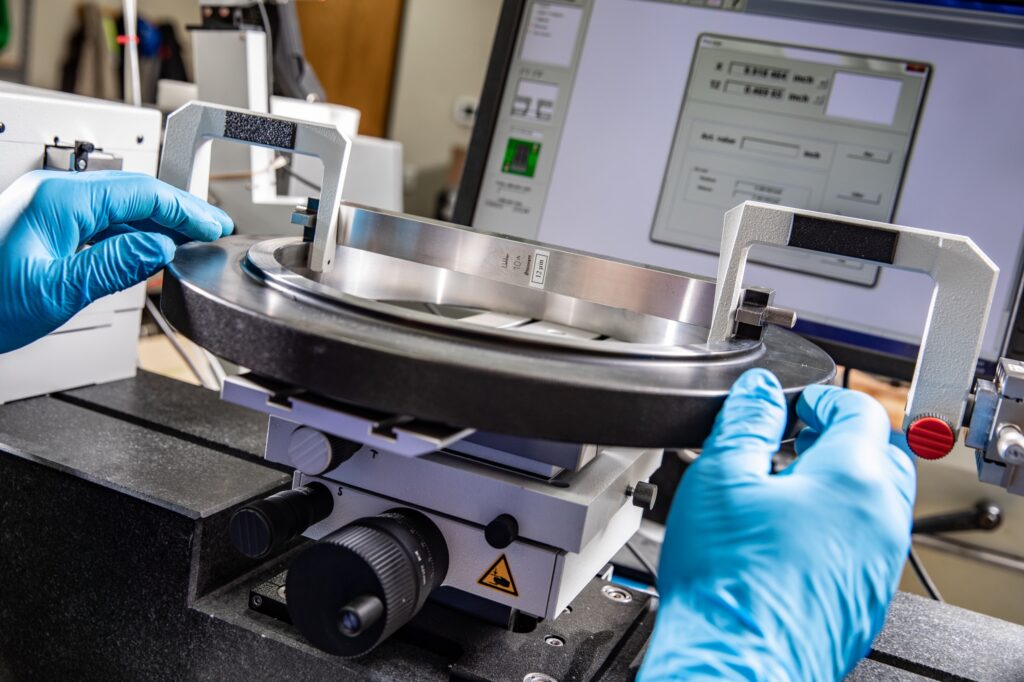

To keep pace with the fast-changing technological landscape, the field of metrology and calibration is continuously evolving. One significant trend is the shift towards automation and robotics. Automated calibration systems not only enhance precision but also improve efficiency by reducing human error and increasing throughput. This is particularly important in industries with high production volumes, where even minor delays can lead to significant financial losses.

Furthermore, the integration of the Internet of Things (IoT) has transformed calibration processes. IoT-enabled devices can communicate with calibration systems in real-time, providing continuous monitoring and ensuring that measurements remain accurate throughout the lifecycle of a product. This proactive approach to calibration minimizes downtime and ensures consistent quality.

The adoption of big data analytics is another trend shaping the future of metrology and calibration. By analyzing vast amounts of measurement data, industries can identify patterns and trends, enabling predictive maintenance and optimization of processes. This data-driven approach not only improves accuracy but also enhances overall operational efficiency.

The Relevance of Calibration Services

In this ever-evolving landscape, calibration services, specifically electronic, dimensional, and mechanical calibrations, are more relevant than ever. Electronic calibration ensures the accuracy of devices and instruments used in various applications, from consumer electronics to aerospace systems. Dimensional calibration guarantees that components and assemblies meet precise specifications, crucial in industries such as automotive and aerospace. Mechanical calibration ensures the accuracy of force, torque, and pressure measurements, vital in manufacturing and quality control processes.

By providing these essential services, calibration labs like ours play a pivotal role in supporting technological advancements. Our ISO 17025 accredited mobile labs are designed for efficiency, ensuring that tools and instruments are calibrated accurately and returned the same day. This minimizes production delays and ensures that industries can maintain their fast-paced operations without compromising on quality.In conclusion, as the world continues to advance at a rapid pace, metrology and calibration remain indispensable. By ensuring the accuracy and reliability of measurements, they enable technological progress and innovation. The milestones achieved over the past 20 years and the continuous evolution of the field highlight the importance of metrology and calibration in shaping a precise and efficient future, driven by the ongoing advancements in metrology that are setting new standards and pushing the boundaries of what is possible.

Leave a Reply